A refrigerated or ‘reefer’ trailer has a refrigeration unit at the front which can heat or cool the load depending on the ambient temperature. It allows for temperature-sensitive goods to be transported long distances.

In some parts of Australia, temperatures can range from freezing point to +40 Celsius in a matter of a few hours. Transporting temperature-sensitive produce such as strawberries requires a vehicle that can maintain a temperature within a 3-4-degree range for a long period of time.

Reefers can be semitrailers, b-doubles, pull trailers, containers or trucks. All that’s needed is a chiller unit to cool an area that’s loaded. It’s easier to cool a white reefer than a black reefer; heat transfer through the body is one of the major considerations when transporting sensitive loads.

The walls of the truck or trailer will either be a box body or an insulated curtain (‘curtainsider‘). Insulated curtains allow for loading from either side of the truck or trailer along the whole length, as well as the rear, but the curtains can be difficult to work with, especially if it’s windy.

The chiller is powered by a separate fuel source. Drivers need to ensure there’s enough fuel in the tank, especially on long journeys. Typically, a full tank will last a few days, depending on the difference between the temperature of the load and the outside temperature.

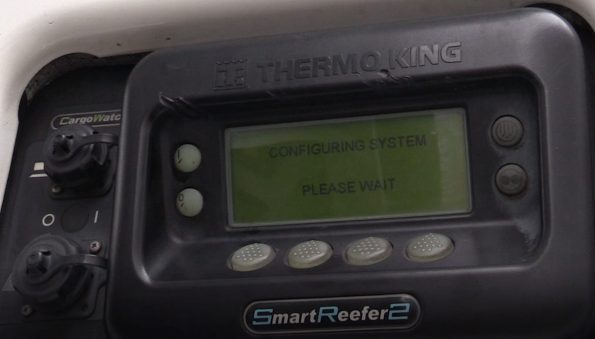

The loading compartment’s temperature is set by a thermostat.

It pays for a driver to know roughly how long it takes for the chiller unit to get to the correct temperature – turning up to pick up a load with when the truck or trailer is not at the right temperature might mean the truck is rejected and asked to return several hours later.

Some chiller units can be remotely controlled and monitored which helps with managing fuel.

At the front of the space, the chilled air is blown out of a vent, usually across the top of the load (cold air sinks).

Inside the chilled area, the floor usually has channels to allow the air to flow underneath the goods. Goods should be packed close to the front of the chilled area to prevent air only circulating at the front, and should not be packed so high or tight that cool air can’t flow around it (a gap of 80-100mm is advised). All stacks should be the same height and it’s best to use the entire floor area.

Where a partial load is being transported, or where the trailer supports dual temperatures, thick bungs can be used. This is more efficient as the space that must be chilled is smaller.

At the rear, the doors must close with a good seal so that heat transfer doesn’t occur between the outside and inside air. However, chillers may need to be vented periodically when transporting products that give off carbon dioxide as they ripen, depending on the instructions given by the consignor.

If you need one for your business, here’s how to check out a reefer truck or trailer.